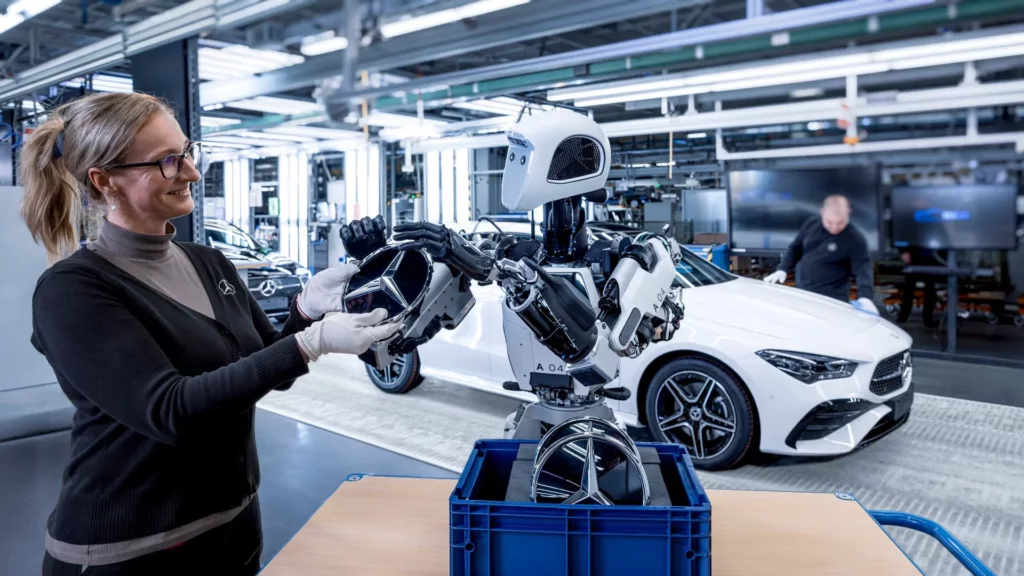

Mercedes-Benz has teamed up with Apptronik to deploy the humanoid robot, Apollo, on its production line. This innovative pilot program aims to enhance manufacturing efficiency by integrating robotics into the workforce and supporting skilled human workers in building Mercedes-Benz cars.

Humanoid robots are swiftly making their way into various industries, with Apollo joining the ranks at BMW and Digit at Amazon. According to Goldman Sachs, the global humanoid industrial robot market could reach US$38 billion by 2035, with analysts noting that “humanoids are particularly appealing for tasks that are ‘dangerous, dirty and dull.'”

Mercedes-Benz’s collaboration with Apptronik marks a significant step towards leveraging robotics to alleviate workers from repetitive and physically demanding tasks. Jörg Burzer from Mercedes-Benz Group emphasized, “We are exploring new possibilities with the use of robotics to support our skilled workforce in manufacturing.” This partnership signals a shift towards optimizing labor resources and enhancing productivity in automotive manufacturing.

ALSO READ: Mercedes Collaborates with Binghatti to Build the mercedes-benz Places tower in Dubai

Apollo, standing at 5.67 feet and weighing 160 pounds, is designed to work alongside human operators in manufacturing environments. Equipped with powerful arms capable of lifting to 55 pounds, Apollo excels at handling physically demanding tasks efficiently and safely. The robot’s unique force control architecture ensures seamless interaction with human workers, emphasizing safety and productivity.

According to the Austin-based robotics startup, “As part of the agreement Apptronik and Mercedes-Benz will collaborate on identifying applications for highly advanced robotics in Mercedes-Benz Manufacturing.”

ALSO READ: Mercedes-Benz Hits the Brakes on Electrification: Prioritizes Profits Over EVs (For Now)

The Financial Times reports that the Apollo pilot is taking place at a Mercedes manufacturing facility in Hungary, where there’s a labor shortage in the auto industry. The company will look into different use cases for the robot helper on the production line, including delivering components and kit totes to workers on the factory floor while simultaneously inspecting the parts.

Apptronik CEO and co-founder, Jeff Cardenas, predicts a trend where organizations replicate Mercedes’ model use case, integrating robots like Apollo to streamline operations. As the pilot progresses, Mercedes-Benz and Apptronik will continue exploring potential use cases and scaling up robotic assistance in automotive manufacturing.

When we set out to build Apollo, an agreement like the one we’re announcing today with Mercedes-Benz was a dream scenario. Mercedes plans to use robotics and Apollo for automating some low-skill, physically challenging, manual labor – a model use case which we’ll see other organizations replicate in the months and years to come,” said Jeff Cardenas, co-founder & CEO of Apollo