Xiaomi, the renowned smartphone manufacturer, has ventured into the automotive industry with the grand unveiling of its inaugural vehicle, the SU7 sedan. The SU7 marks Xiaomi’s foray into car manufacturing, with production already underway at the state-of-the-art Xiaomi Super Factory in Beijing, China.

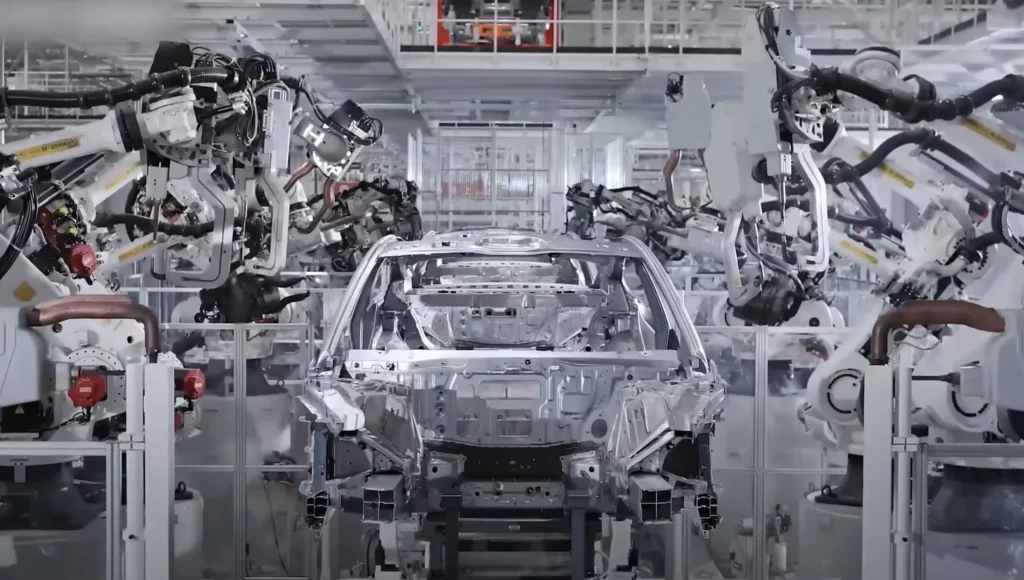

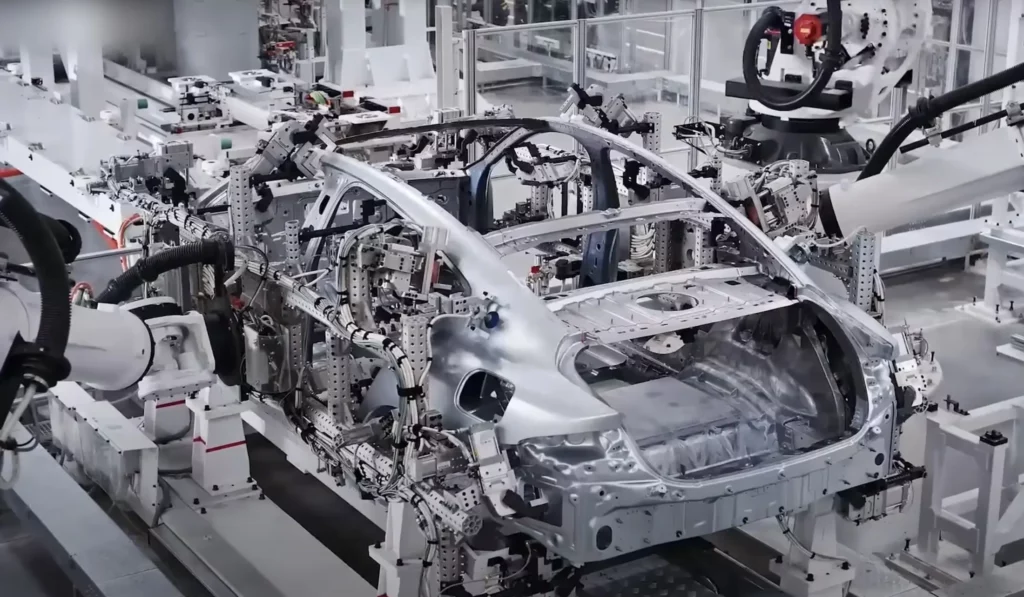

At the Xiaomi Super Factory, a new SU7 sedan emerges every 76 seconds from the assembly line, showcasing an impressive capacity to produce 40 cars per hour. This swift pace is made possible by cutting-edge automation technologies, spearheaded by over 700 meticulously programmed robots. These robots efficiently carry out intricate tasks ranging from installation to inspection, ensuring precision and efficiency in every stage of production.

In the body shop alone, 381 robots work in seamless collaboration with 20 skilled employees, accelerating assembly processes to under 30 seconds per component. This level of automation not only enhances productivity but also underscores Xiaomi’s commitment to innovation in the automotive sector.

ALSO READ: Xiaomi’s Electric Vehicle Launches in China: SU7 Sedan Unveiling on March 28

Founder Lei Jun announced the upcoming ceremony at the EV factory in Beijing on Weibo.

“Tomorrow is the big day as we will be holding our first delivery ceremony for Xiaomi SU7 at Xiaomi EV Factory in Beijing. This will be followed by 28 other delivery centers in cities across the country

LEI JUN, FOUNDER AND CEO OF XIAOMI/X (credit dewdiver)

Lei Jun, Founder, Chairman, and CEO of Xiaomi, has strategically steered the brand into this new venture, aiming to disrupt the automotive landscape with cutting-edge technology and efficient manufacturing processes. The SU7’s production highlights Xiaomi’s transition from a smartphone giant to a formidable player in the automotive market.

The SU7’s assembly process is revolutionized by the integration of smart techniques and robotic precision. Each stage, from body construction to final finishing, is optimized for speed and quality, significantly outpacing traditional manufacturing methods. Robotic arms meticulously handle tasks such as door installation, bolt tightening, and windshield fitting within seconds, showcasing Xiaomi’s commitment to efficient production.

Xiaomi’s smart paint shop further enhances efficiency with its flexible color sorting technique, allowing rapid color changes within a mere 40 minutes. This innovation significantly reduces order delivery times by up to 25%, highlighting Xiaomi’s dedication to customer satisfaction and streamlined production processes.

Despite its ambitious debut, Xiaomi has faced challenges typical of a new entrant in the automotive industry. Recent reports of test car mishaps have surfaced on social media, highlighting the need for swift resolution before customer deliveries commence. The company is actively addressing these issues to ensure the SU7’s safety and performance meet customer expectations.

“A throwback to last week when I delivered our first Xiaomi SU7 in Xiaomi EV Factory, Beijing. The trust that owners have put in our dedication to deliver high-quality EVs and exceptional service is the most rewarding experience “

LEI JUN, X

ALSO READ: Xiaomi SU7 Electric Sedan Sold Out 88,898 Orders Within 24 Hours

Demand for the SU7 has been unprecedented, with Xiaomi receiving a staggering 50,000 reservation requests within half an hour of opening reservations. This overwhelming response underscores the model’s popularity and anticipation among consumers. However, extended waiting times have prompted some customers to seek refunds, highlighting Xiaomi’s need to streamline production and delivery processes.

According to Reuters, customers who reserved the SU7 Pro version will need to wait around 18 to 21 weeks for delivery. For those who opted for the top-tier SU7 Max, the waiting time is approximately 30 weeks. Xiaomi plans to begin delivering cars this April.